Forced labor regulations are on the rise, and brands and retailers that turn a blind eye risk much more than a missed shipment – they risk costly delays, reputational damage, and even lost partnerships.

For brands importing merchandise, forced labor compliance demands a full, documented breakdown of supply chains – a step-by-step, verifiable record of every material and labor source involved.

‘Trust but verify’ must be the mantra for resilient, compliant brands in this environment.

1. Rising legislative pressure

Forced labor compliance is not limited to just one region or regulation. In addition to the U.S.’s Uyghur Forced Labor Prevention Act (UFLPA), which bans imports linked to high-risk regions, importers must also comply with other established and upcoming forced labor regulations across the world.

Canada and Mexico implemented their own laws under the U.S.-Mexico-Canada Free Trade Agreement (USMCA), and the EU is set to prohibit the sale, import, and export of goods made using forced labor by mid-2027.

Each regulation requires deeper transparency across supply chains and increased due diligence to identify and eliminate forced labor risks.

Brands must actively understand – and verify – the origins of every material that flows through their products to protect their business and revenue.

2. Limited transparency beyond tier one

Forced labor risks do not stop with tier one or direct suppliers providing finished products. They lurk deeper, especially in tier 3 and 4 suppliers, where cotton gins, farms, and raw material processors operate.

For example, during the laydown stage at the spinner’s facility, when the raw cotton bales from various sources are brought together and opened, there is a chance of forced labor entering the supply chain. During weaving, yarn may be unknowingly substituted for forced labor-tainted yarn to maintain margins.

There are many ways cotton from high-risk regions can feed into the supply chain, but without a verification system to catch these issues, companies may never know the truth about their products.

Testing a physical product helps companies mitigate risk by verifying that the claimed origin matches the actual origin.

3. Unverified supplier claims

Trusting that a supplier’s signature means compliance is no longer a viable strategy.

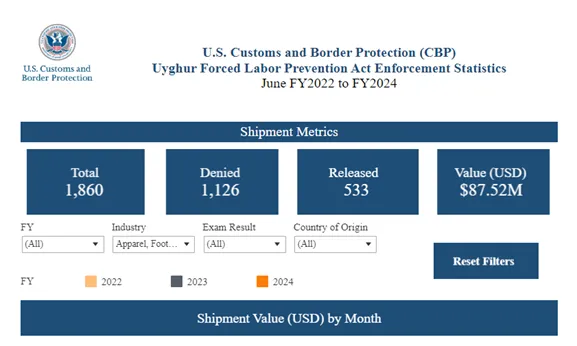

With detentions from U.S. Customs and Border Protection (CBP) hitting apparel shipments at record levels, vendor contracts containing “no forced labor” clauses are not enough to defend importers from Withhold Release Orders (WROs) or other enforcement actions.

Brands and retailers need more than written certifications and verbal promises from suppliers to avoid the risk of forced labor in their supply chains. They need independent verification methods, such as Oritain’s forensic science technology, which add an extra layer of scrutiny to their supplier claims.

Without verification, brands could find themselves blindsided by regulatory enforcement, paying for compliance in many ways.

4. Transshipments concealing origins

Transshipments, or the rerouting of goods through intermediary countries to disguise their origins, present a growing challenge to forced labor compliance. For some suppliers, this tactic allows them to obscure connections to high-risk regions to skirt scrutiny. This practice muddies supply chains by adding a layer of opacity, leaving brands exposed to risk.

Depending solely on “entity lists” or other sanctions to identify these agile, high-risk suppliers – who may rebrand, shift ownership, or move operations to new locations – is a game of whack-a-mole.

Proactive testing and verification can cut through the smokescreen and reveal where the raw materials and products are actually coming from, regardless of where they were processed or assembled.

5. Lack of quantifiable, reliable data

Forced labor risks are often overlooked due to the lack of quantitative and reliable data. Many companies rely on implicit or indirect information, such as supplier invoices and statements, rather than quantifiable data derived from scientific analysis of raw materials or fabrics.

This data-driven approach not only provides more accurate and reliable assessment than traditional supply chain mapping tools but also empowers brands to substantiate the authenticity of supplier information. And if discrepancies arise, they can quickly scrutinize other subjective data sources and make informed decisions.

Oritain, a global leader in origin verification, employs forensic isotopic testing – a trusted and quantifiable method for verifying the origin of raw materials and products. Leveraging advanced technologies like isotopic analysis and multivariate statistical modeling, this approach is grounded in established science used in criminal investigations worldwide. Additionally, Oritain has created proprietary methodologies and models for high-resolution testing and verification of the origin of cotton in commercial supply chains. This includes patent-pending methods for sample preparation that enables the isolation and testing of cotton in blended materials including cotton blended with synthetics, keratin fibers, and regenerated cellulose fibers.

Unlike other isotopic providers who may rely on databases with nominal populations or developed from fabric samples to provide verification, Oritain has the largest cotton reference database in the world. This database is comprised of hundreds of thousands of individual samples that have been collected as primary samples directly from cotton farms, which ensures that the foundation of the scientific verification is underpinned by original, unadulterated data directly from the sourcing origins. Oritain's unparalleled database, alongside its proprietary statistical and data models, provides the highest level of accuracy, reliability, and scientific validity to meet compliance and legal standards.